machining surface finish grades

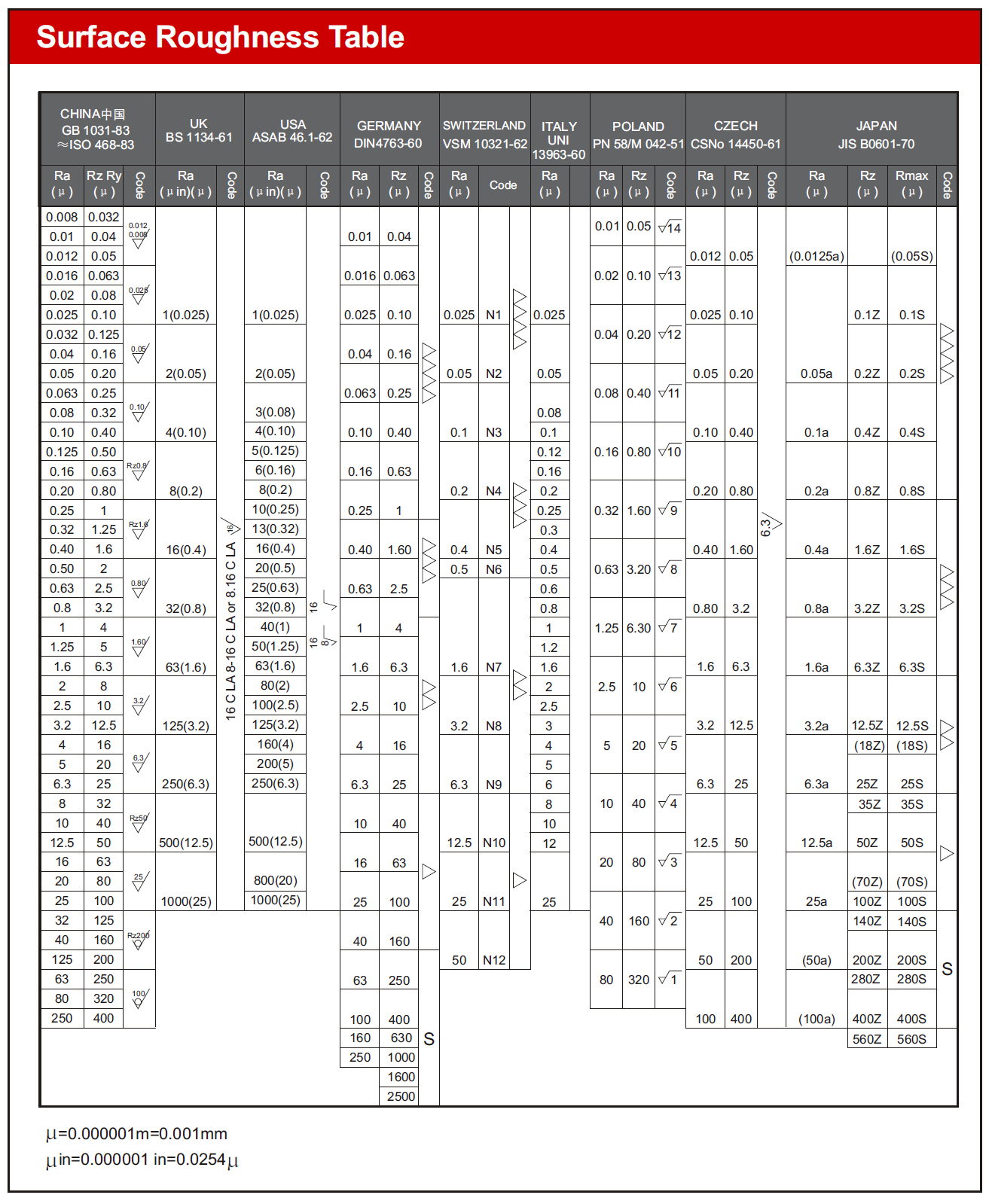

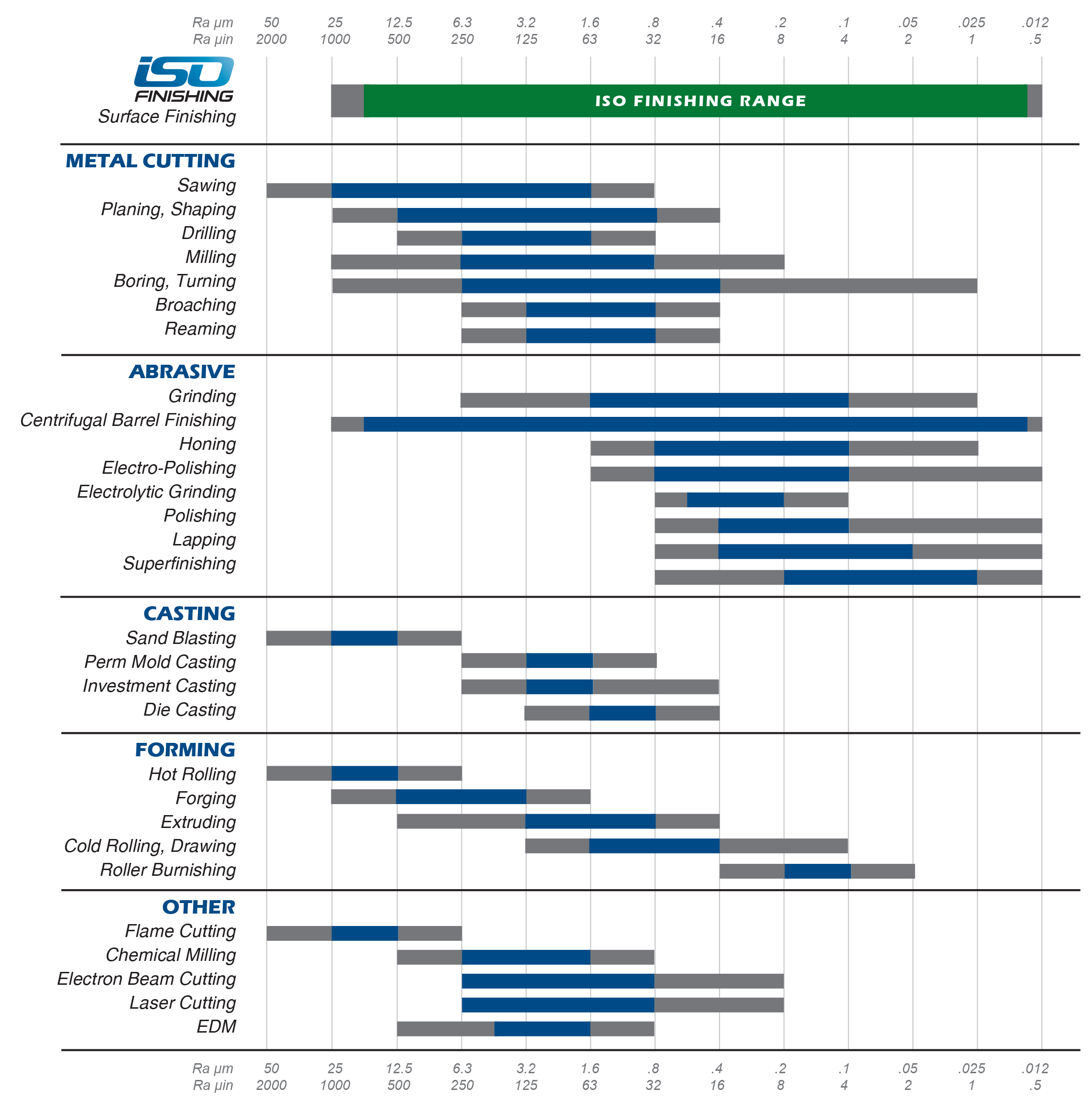

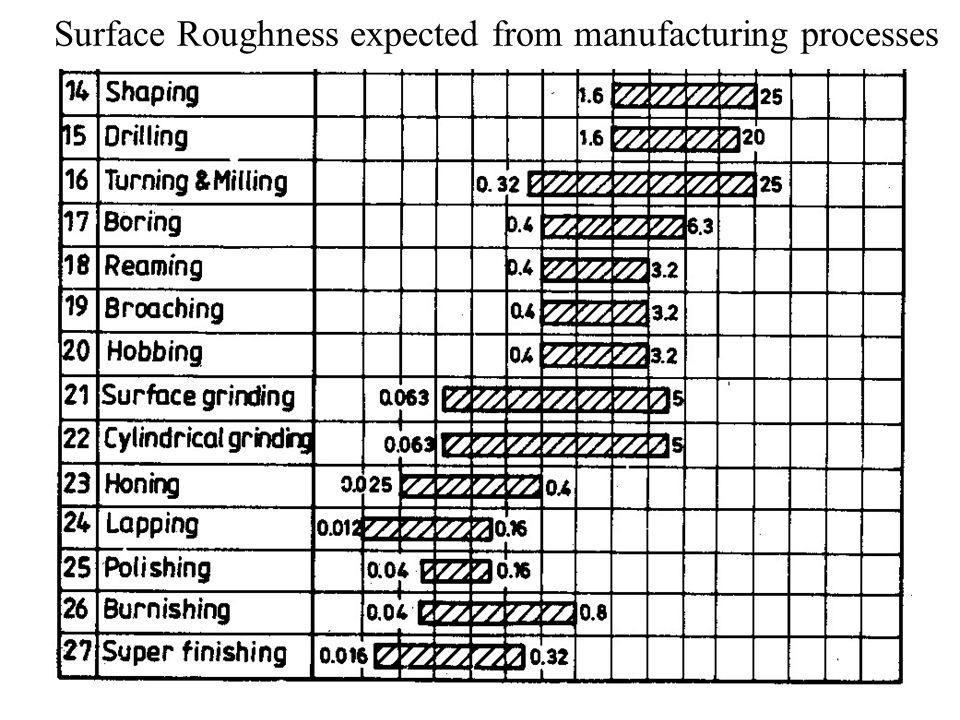

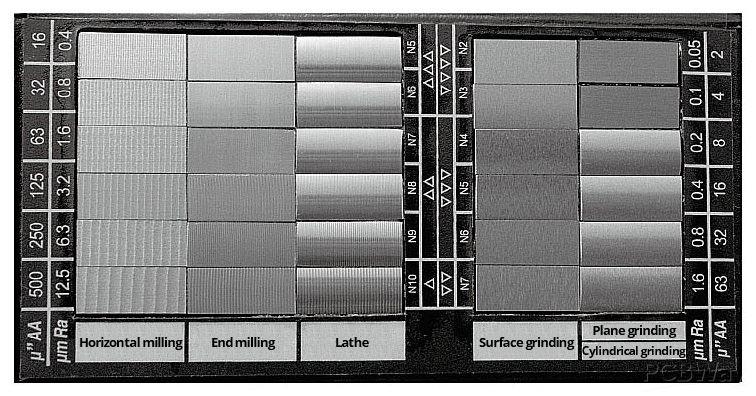

Machining N9 250 63 N10 500 125 Rough. The chart lists the name of the finish the roughness in microns and the applications.

Surface Roughness Explained Get It Made

Ad For Precise Machining and Remarkable Surface Finish.

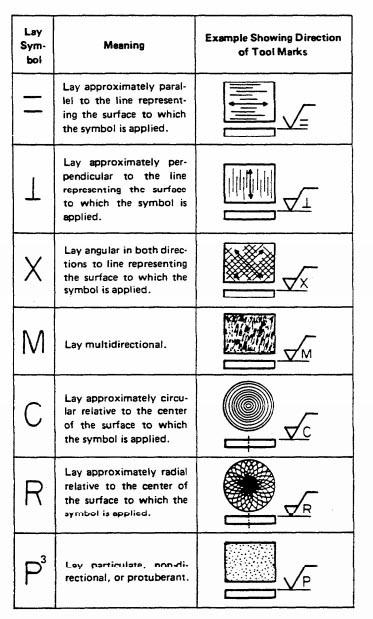

. 22-Jun-12 Kirloskar Pneumatic Co. Finish Symbol N Finish R a μinch R a μm Super finishing. It refers to a surfaces minor local deviations from a perfectly flat surface an actual plane.

Machining symbols and Surface. N6 finish will need to be machined. Surface Roughness Grades.

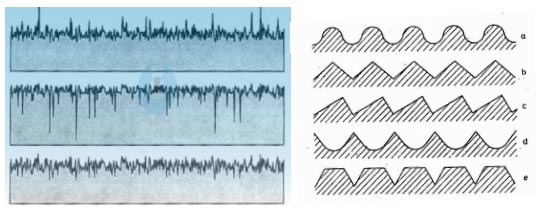

Roughness consists of surface irregularities which result from the various machining process. The nature of a surface is known as surface finish or surface topography. Surface finish specification and comparison.

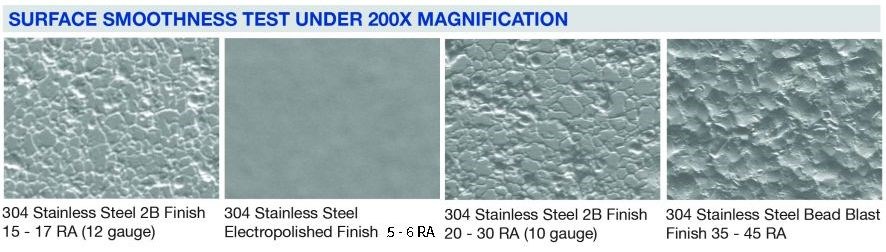

This can improve the resistance of the steel parts to corrosion and. The name already explains what the concept stands for. Surface finishes are applied after machining and can change the appearance surface roughness hardness and.

Surface finish requirements can be increased to 16 08 and 04 μm. Yes to Teds answer. An engineering component may be cast forged drawn.

N1 1 0025 Lapping. There are 3 main ways to acquire the surface roughness value. The plastic surface finish chart is a guide to the various finishes that can be applied to plastic parts.

Manufacturers always use it as reference material to ensure quality in the. Surface Roughness Terminology. There are a total of 12 grades of surface finishes and those grades are grouped into 4 categories.

Surface finishing is also referred to as surface texture surface roughness or surface topology. These irregularities combine to. The measure of the total space irregularities on the surface metal is known as Surface Roughness.

For instance when manufactured products possess smooth surfaces they. It also depicts the number of peaks and valleys on a surface. The machining surface finish chart offers important guidelines for measuring standard surface finish parameters.

Machining surface finish influences the quality durability and performance of manufactured parts and components. As Machined parts have minor visible tool marks. Machining surface finish grades Sunday June 5 2022 Edit.

Surface finish Also called sometimes surface roughness is a numeric representation of a surfaces smoothness. This surface finish involves electroplating steel metal by adding a thin layer of nickel around 01 mm. You can get a N9 finish for sure with a bandsaw N8 if you are using a good blade with fine teeth.

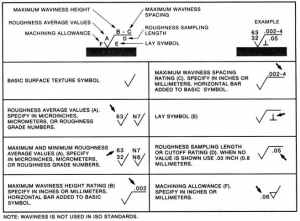

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Machining Surface Finish Chart Conversion Comparator Method Degree Ra Rz Rms

Surface Roughness Chart Comparison Iso Finishing

Surface Finish An Engineering Component May Be Cast Forged Drawn Welded Or Stamped Etc All The Surfaces May Not Have Functional Requirements And Need Ppt Video Online Download

Stainless Steel Finishes Explained En Astm Fractory

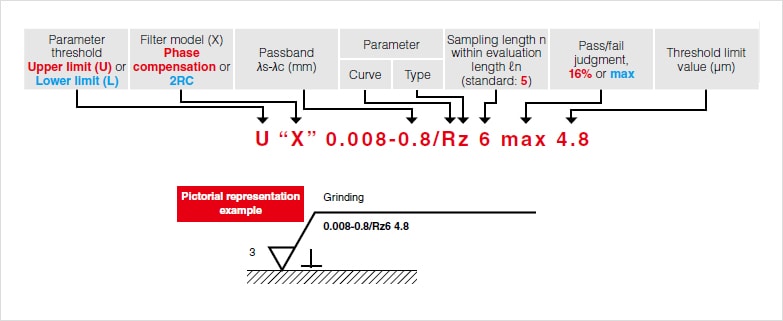

Understanding Surface Roughness Symbols Introduction To Roughness Keyence America

The Basics Of Surface Finish Gd T Basics

The Complete Guide To Surface Finishes Xin Tian Jian Precision Mfg Ltd 2022 October

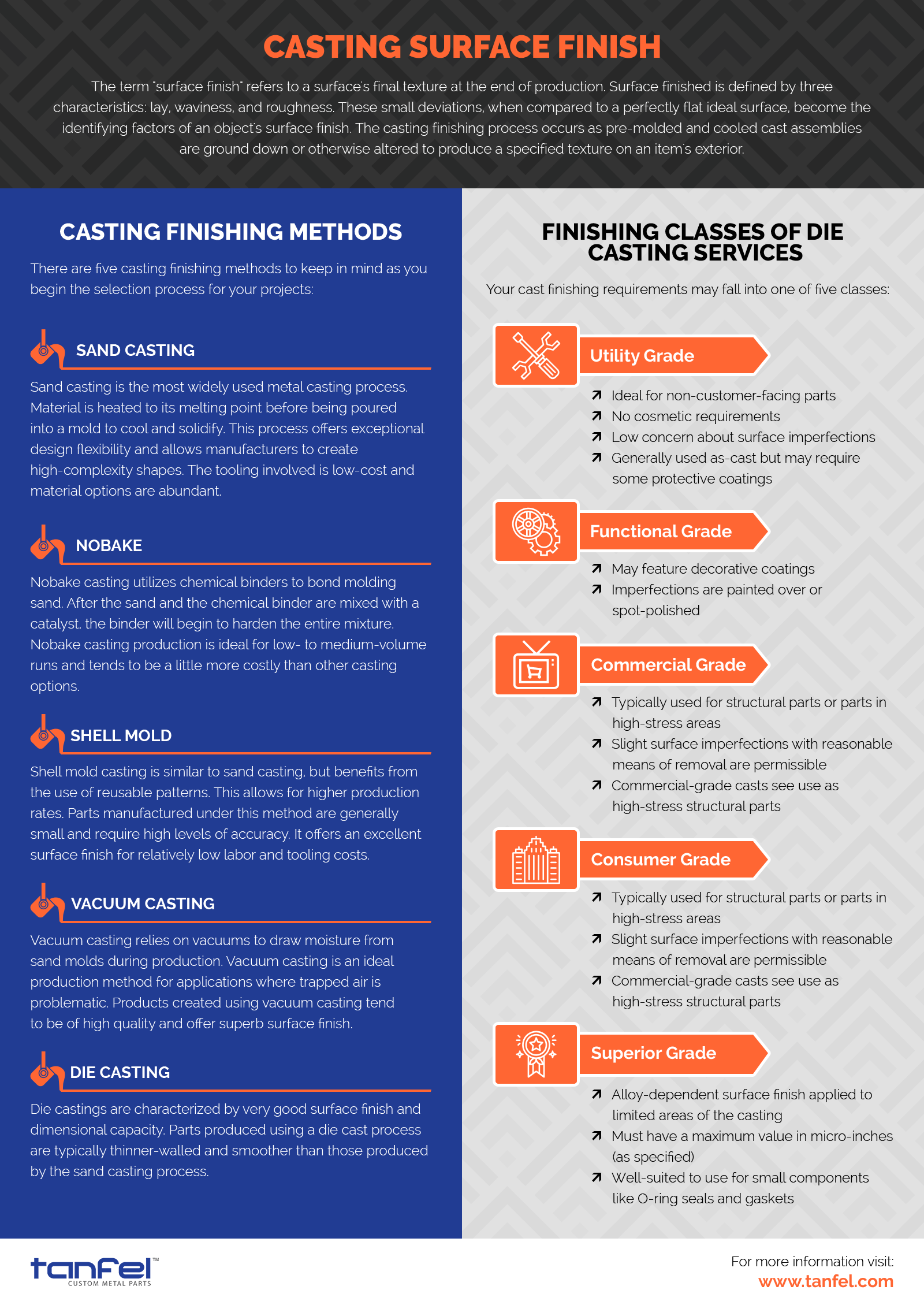

Casting Surface Finish Sand Casting Die Casting More Tanfel

Surface Roughness Indication Symbols Surface Roughness Symbol Indication In Hindi Youtube

Surface Finish Surface Roughness It S Indications Symbols

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Finish Surface Roughness Symbols Charts Callouts Costs

Surface Finish Surface Roughness It S Indications Symbols

Selecting Right Surface Roughness For Cnc Machining Xometry Europe

Mastering Sanitary Stainless Steel Finishes Products Finishing

Selecting Right Surface Roughness For Cnc Machining Xometry Europe